The process of manufacturing a steel window is a complex and time-consuming one, involving a high level of expertise and attention to detail.

All Clement steel windows and doors are made bespoke to individual orders in our own factories. We employ the best cutters, welders and glaziers who utilise technology wherever possible, with a strong emphasis on hand crafting, to produce the beautiful, high performance steel frames which Clement is well known for. We also follow rigorous quality control and testing procedures which ensure that our premium steel windows and doors meet the high standards clients associate with us.

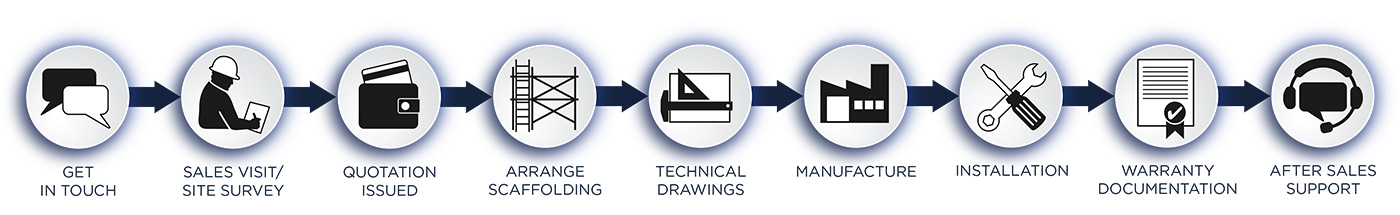

It is important to us that we collaborate with clients at every stage of the process as this will result in the most timely and satisfactory outcomes for everyone involved. Below we have outlined the different stages that a typical client can expect to go through on the journey to creating a steel window or door.

This is the start of the process. We are unable to give quotations over the phone. Get in touch by calling us, emailing us or filling in our online form. It is important that you give us as much information as possible at this stage. Photographs, detailed elevations and other drawings and measurements are all useful to help us to action your enquiry.

We would prefer to visit the site to obtain all relevant information at this stage in the process. However, we understand that some clients are only looking for an indicative quotation at the outset, in which case (3) below would precede this stage.

Once you have placed your order and paid the initial deposit, our Sales/Survey Teams will contact you to arrange a site visit to measure your windows and to agree size and specification details. It is important that you provide us with all the details we need at this stage as if anything is omitted this can cause delays further down the line.

See note above under (2).

We aim to respond with an initial quotation based on the information you have provided within 3-5 days, but this is dependent on the type and scale of your project.

Please check that the quotation includes all the elements you need. If you are happy, please fill in and return the Order Acceptance Form to us. This needs to be returned with a deposit as outlined in your quotation.

Please note that following the issue of the quotation if there is a delay in us receiving the order then the quoted lead times will change by the period of delay and potentially volume of work issues known at that time.

It is your responsibility to ensure the correct scaffolding is in place to comply with weight carrying and health and safety regulations.

All fixed scaffold provided needs to be erected by a registered company and the relevant handover certificate provided prior to our installation teams arriving on site. We are able to provide advice on this, so please let us know early on if you need us to do so.

Following the site survey, we will prepare technical drawings for you to approve.

You will need to check that the drawings reflect your requirements, especially in terms of opening arrangements, colour and type of handles/fittings. If you are working with a builder or other third party, we recommend that you obtain their agreement to the drawings to avoid any problems later on in the process.

The manufacturing lead time only commences once the drawings have been approved and we factor in one week for preparation of manufacturing drawings and guidelines. Any delays will affect the manufacturing lead time. If you make alterations to the drawings after this stage there will be delays to your order as well as potential additional costs.

Once you have approved the drawings, they will be submitted to our factory to be added to our production schedule and we will advise you of a scheduled installation date. Please note that the manufacture of a steel fenestration product is a complex and lengthy process, including hot dip galvanising and polyester powder paint coating to meet advanced performance standards. Clement uses an internationally recognised Quality Management System, ISO 9001, for design, manufacturing and installation systems and ISO 14001, for environmental management. All our windows and doors are tested and certified before leaving our factories.

If your project is delayed in any way, please let us know as soon as possible. Our fitting teams are booked weeks in advance so the earlier we are advised of any changes the more likely we will be able to fit in with your plans.

Around four weeks before the scheduled installation you will be contacted by our Intallation Team to confirm the start date. Around one week before that date we will call you to ensure everything is running to schedule and that you are ready for us.

Once your installation is complete a member of our team will take you to the windows/doors so that you can inspect them and sign the work off.

After you have signed off the job and as long as the full balance has been paid we will issue the warranty documentation.

Post installation, our Client Services team is still available to support you should you have any questions or in the unlikely event that any issues arise. They can be contacted on 01428 643393 or info@clementwg.co.uk.

For information on our current lead times, please contact the Sales Team on 01428 643393 or info@clementwg.co.uk.

The process for our conservation rooflights is different as our standard sizes are available from stock. Please visit our rooflights product page for more information or call 01428 643393 to speak to someone in our rooflights department.