01428 643 393

NEWS

May 23rd, 2019

The decision to install new steel windows or contemporary steel screens into your home is a big one, requiring plenty of thought and planning. The end result is a dramatic transformation that brings better insulation and security and plenty of light to your property. But it’s not often that we think about the origins of these beautiful metal windows or how they came to be. Here we outline a brief history of how steel windows are made and look at their journey from the factory to your home.

We’ve previously touched upon the history of metal windows and how they were originally made from wrought iron in a blacksmith’s forge centuries ago. At this time, clear glass could only be produced in small panes, leading to the creation of the diamond patterned glazing bars that we still use today.

By the mid 1800s, a process for hot rolling steel made the creation of steel windows possible, quickly leading to them becoming popular in the construction of both homes and commercial buildings and much admired for their adaptability, strength and beautiful appearance.

Today, whilst the hot rolling design is still faithfully adhered to for producing the steel window frame, modern advances in steel manufacturing enable us to produce steel windows at a much faster rate, with hot rolling and pressing carried out by industrial machinery.

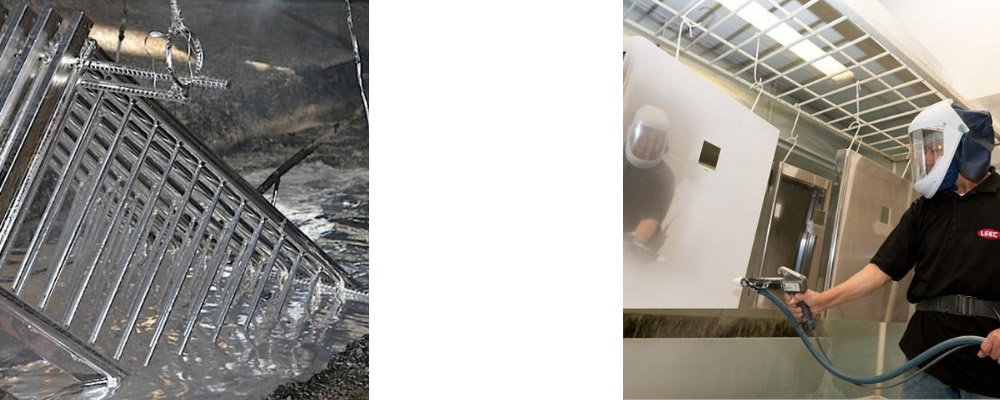

The steel bars are welded together to form the frame unit and then hot dip galvanized, a pre-treatment process that protects the material from corrosion over time. This process which was introduced during the 1950’s was integral to the development of steel window manufacturing contesting the common misconception that steel will rust over time.

The frames are then fettled by hand so that their surfaces are ready for paint coatings. At Clement Windows, we use a powder coating that enables us to finish your steel windows in almost any colour you choose, meaning we can create truly bespoke schemes to fit your home.

Finally, the frames and components are assembled by hand to create the finished window, rigorously tested and then carefully packaged to be delivered to your property. The end result, as you can see, is a window product which is a world away from its origins as raw steel.

If you’d like to see more examples of Clement steel windows and screens in a residential environment, click here to see some of our case studies. Alternatively, if you’d like to request one of our brochures, you can do so here.